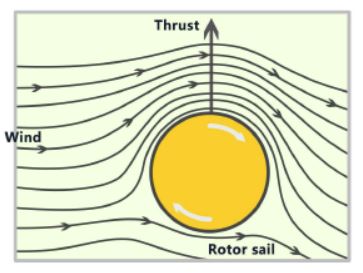

Dealfeng Rotor Sail Technology is based on the Magnus effect to generate forward thrust to provide auxiliary propulsion power for the ship.

When wind flow meets the spinning Rotor Sail, the air flow increase on one side and decreases on theother side of the Rotor Sail.

This thrust force can be used to increase the ship speed or reduce the the main engine' s fuel consumption. The same principle appliesto all rotating spheres or cylinders.

Dealfeng Rotor Sail in particular, is an innovative fully automatic mechanical Flettner Rotor that harness the power of wind to generate auxiliary propulsion thrust for ships through Magnus effect.

When the wind meets the rotating cylinder (Rotor Sail), the air flow accelerates on one side and decelerates on the opposite side, which causes differential pressure around the rotor sail.

The pressure difference creates a forward thrust that propels the shipthrough the water. Thereby, the ship can reduce the fuel consumption and thus lowerGHG emission by.

At the beginning of the uptake of wind propulsion technology, most people think that the Rotor Sail is used to generate electricity for propel the ship forward.

Actually, the Rotor Sails CAN’T be used to generate electricity.

The Rotor Sails require external electrical power to rotate them in order to produce useful thrust by Magnus effect.

Dealfeng Rotor Sail takes small deck space with a safe, reliable, fully automatic and long-running system. New-build ship or retrofit ship with the installation of Rotor Sail system can effectively improve the ship' s EEDI, EEXI, CII.

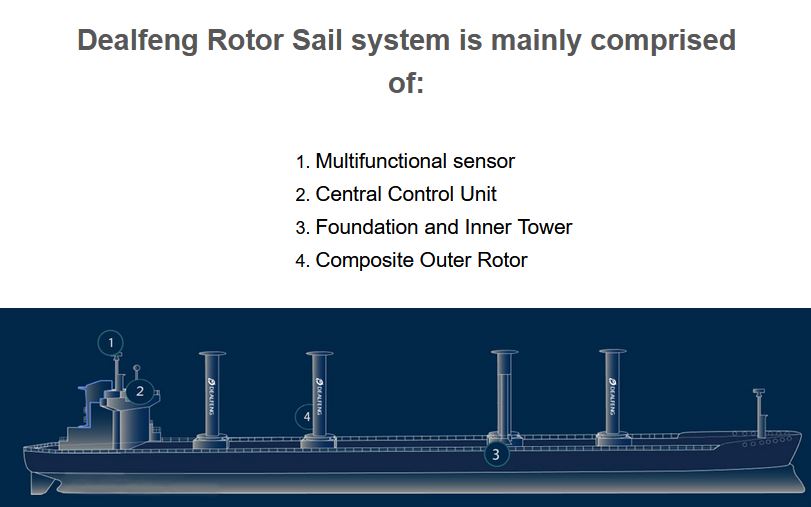

Compared to other WAPS in the market, Deafeng Rotor Sails offer a much greater thrust force to the ship forward, occupying small lateral projection area, and the weight is relatively light. Sail is divided into five parts below:

- Multifunctional sensor

- Dealfeng control system & mechanic-electrical systems

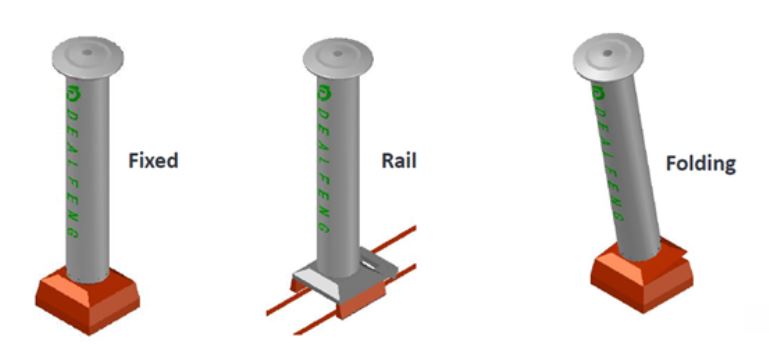

- foundation (Fixed, Folding and Rail)

- Inner tower

- Composite rotor.

After actual verification on more than 30 ships, the comprehensive fuel saving rate of the wind assisted propulsion system is 5% - 30%. The specific fuel saving rate depends on the ship type and the number of installed sails.

|

|

We shall be glad to receive your future enquiries concerning rudder systems and mewis duct, you may contact via e-mail: BPCO SHIP BROKERS |

| |