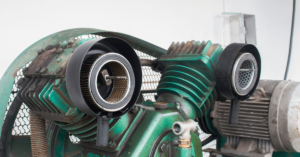

Every Air compressor on a ship is fitted with several safety features to avoid abnormal and dangerous operational errors of the equipment. If safety, alarms and trips are not present on the air compressor, abnormal operation may lead to breakdown of the compressorand may also injure a person working on or around it. Different safety features on an air compressor are

Relief valve:

Fitted after every stage to release excess pressure developed inside it. The setting of the lifting pressure increases after every ascending stage. Normally fitted between 1st stage and intercooler and 2nd stage – aftercooler.

Bursting disc:

A bursting disc is a copper disc provided at the air cooler of the compressor. It is a safety disc which bursts when the pressure exceeds over the pre-determined value due to leaky air tubes of the cooler (intercooler or aftercooler).

Fusible plug:

Generally located on the discharge side of the compressor, it fuses if the air temperature is higher

Content Original Link:

Original Source MARINE INSIGHT www.marineinsight.com

" target="_blank">

Sidebar

Infomarine.Net Menu

Infomarine On-Line Maritime News

Today Maritime News Worldwide

Infomarine On-Line Maritime News

Today Maritime News Worldwide

04

Tue, Mar

![ABS FEED Approval Allows ECO TLP[®] to Begin Project Testing](https://www.infomarine.net/images/joomgrabber/2025-02/c04fae116e.png)