The 66kV high voltage wet mate connector currently undergoing technical qualification by Baker Hughes weighs in at around one ton and has over 40 liters of dielectric…

The 66kV high voltage wet mate connector currently undergoing technical qualification by Baker Hughes weighs in at around one ton and has over 40 liters of dielectric oil protecting copper cable up to 1,200 square millimeters in diameter.

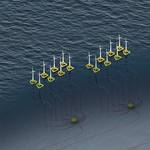

The connector is designed to sit on the seabed at the end of a dynamic cable coming from floating wind turbines and connect it to a collector hub that ultimately delivers the megawatts of energy it produces to a subsea substation and then to shore.

There’s a lot that could go wrong.

Cable failure is a high-cost problem for fixed offshore wind even though, like oil and gas applications, it involves static cabling. Dynamic cable failures are expected to be even more common when the floating wind industry takes off.

Baker Hughes has leveraged its oil and gas experience to redesign and increase the power range of its Marine Electrical Connectors (MECON) high voltage AC wet mate connector to reduce the impact of cable failure. The company’s three-phase wet mate connectors consolidate three connections into a single housing, optimizing insulation fluid cleanliness while minimizing potential leak paths compared to the single-phase connectors used by others in the industry. These require three connections

Content Original Link:

" target="_blank">